|

NATIONAL MUNITIONS

COMPANY

Eldred Building No 35: Tetryl Pressing |

|

|

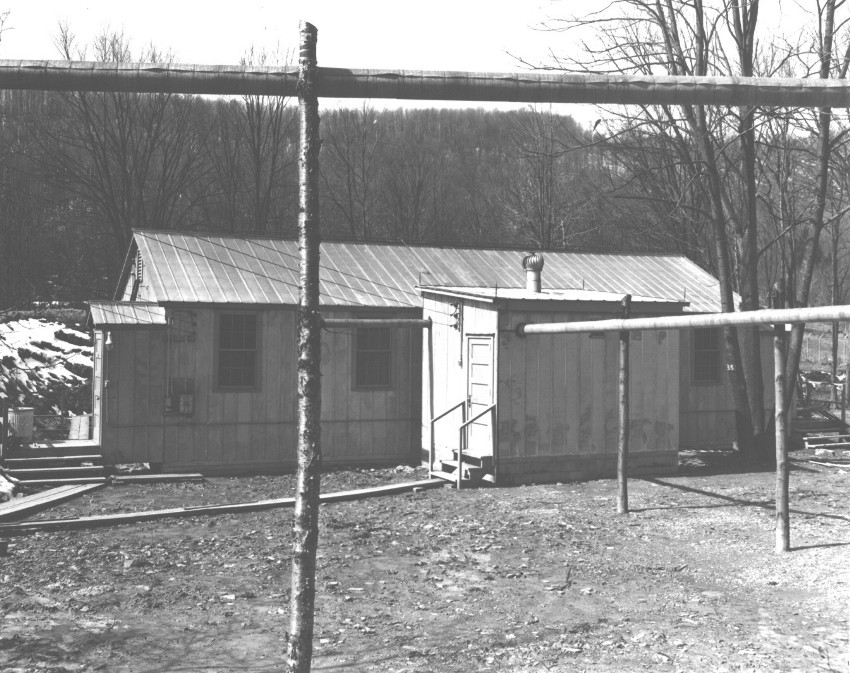

The

Tetryl Press building houses four Tetryl pellet presses for making

Tetryl pellets of various sizes. The building has to be air conditioned

and is barricaded on two sides. The building in the foreground

contains the air conditioning equipment.

|

|

|

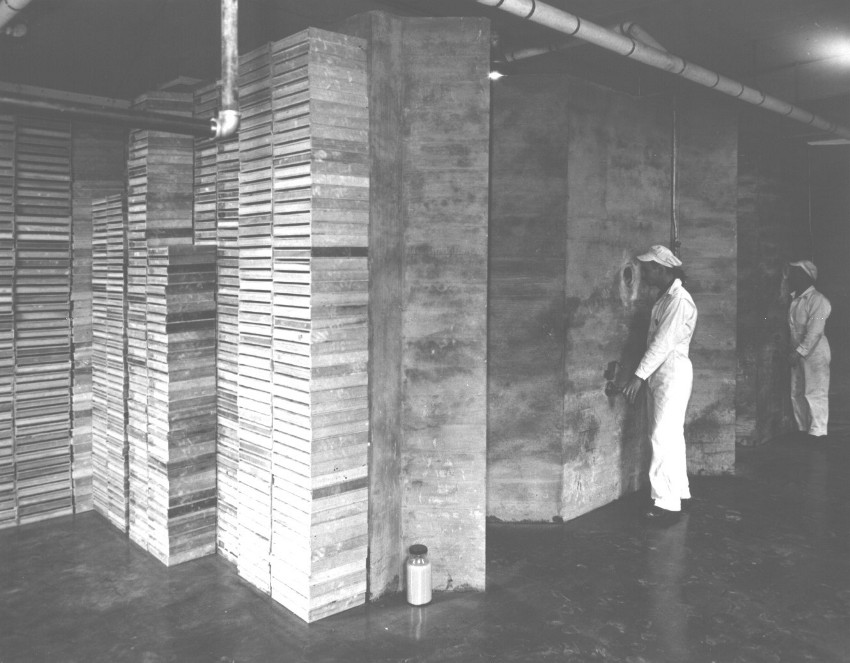

Interior

view of part of Tetryl Press building showing concrete barricades

around the presses. The barricades are of reinforced concrete

six inches thick, and the presses are operated from the outside,

the operator watchingby means of peep-holes and mirrors.

Note empty pellet boxes at the left ready to be filled. |

|

|

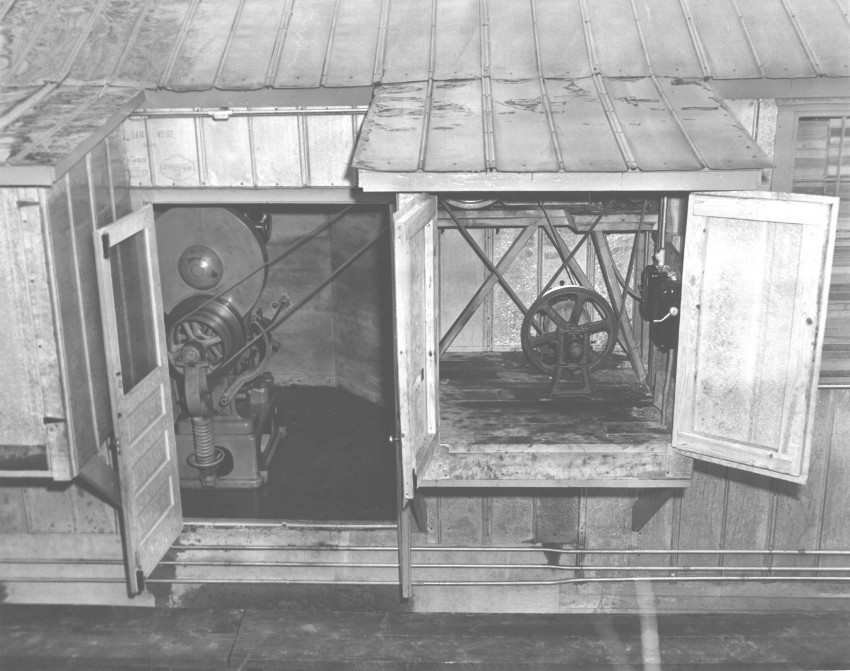

Close

up view of Stokes Pellet Press. Double doors in the outside wall

constitute the back of each cubicle. In case of an explosion these

doors would blow off, and the force of the explosion dissipated

outside instead of inside the building.

|

|

|

The Tetryl Presses

are driven by explosion proof motors mounted outside the building,

in house attached to the outside wall. In this picture both the

double doors back of the press and the door of the motor house

are open to show the arrangement.

|

|

|

Pellet Storage Magazine,

Building No 34. Typical magazine construction - weak mix cement

blocks. When filled with sand, with sand layer under roof, they

are proofed against high powered rifle shots. This magazine is

also air conditioned by the small building left.

|